R&D

01

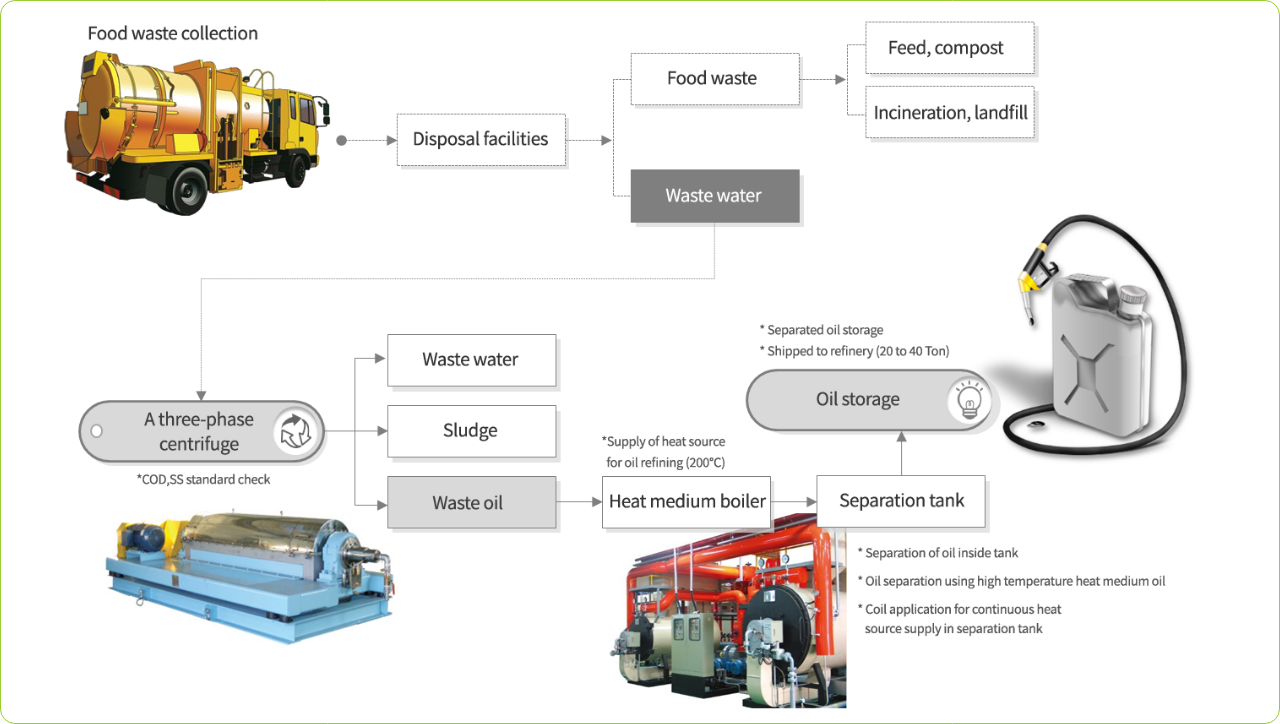

Development of Process Improvement Technology for Food Waste- The General Process of Food Waste Disposal

- The characteristics of food waste in each region differ, and it is required to change the order of processes and develop technologies for high-efficiency treatment processes for better treatment.

- The treatment of oil generated during the food processing process can simplify the process and reduce operating costs, which is expected to have a significant economic ripple effect.

- The separation of oil from negative waste water is a physical separation process using a three-phase centrifuge and a two-phase centrifuge (high-liquid separator). The Sludge in the waste water is also removed in this process simplifying the post-treatment process of waste water.

02

Development of high value-added technology using negative waste oil

Analysis of Food Waste Disposal Process and analysis of the characteristics and measurement of the generation amount of negative waste

water according to various resourceization processes.

- As the treatment methods of food waste vary, the capacity and nature of generated wastewater are systematized by analyzing the characteristics of each process.

- The oil content of negative waste water varies according to season, region, and treatment porosity, so the development of a technology for selecting the capacity of the separation system according to the amount of waste water is required. (Food treatment facilities, wastewater properties, etc.)

Design and system manufacture of oil separation process according to the properties of the negative waste water and optimization of

oil separation process

- Analysis of design and performance determinants of oil separation system

- Preparation of criteria for separation of negative waste water properties and preparation of samples

- Analysis of oil separation process (Investigation of actual application models of competitors and local governments)

Development of cyclone separation technology, per-heater design and manufacturing technology for optimal oil separation process system

complete.

- The negative waste water has seasonal characteristics, which can potentially be a cause which decreases oil extraction efficiency, so a warm preheater is installed to minimize this, and a cyclone is introduced to reduce the sludge content of the negative waste water heated to the appropriate temperature. (It is a unique technology based on patent application)

Development of blending process for separated oil (water and sludge content reduction technology)

- Lab using samples. Based on the development of the reference process of scale, we intend to expand and apply it to the field type.

03

Technology Development to Increase the Recovery Efficiency ofVarious Animal/Vegetable Maintenance

Completion of the Optimal Oil Separation Process System

- Maximize the efficiency of extraction facilities by accumulating process design know-how using centrifugal force according to the nature of maintaining various animals and plants.

-

By analyzing the nature of wastewater generated in the production process, the standards for two-phase and three-phase separation are

established, and the abilities of existing treatment facilities are improved.

- Introduction of Pre-heater section to overcome seasonal characteristic differences in the maintenance of various animals and plants

- Development of technology to reduce sludge content of separated oil (specific RPM setting of centrifuge)

Optimization of moisture and sludge reduction process technology

-

Development of refining tank and accumulation of design technology to reduce sludge of separated oil

- Installation of auxiliary tanks to control the moisture and sludge content of extracted oil

- Development of heating tank design technology using waste heat, heat transer substance and steam (Own Technology Introduced)

- Design and water extraction process technology of heat exchanger inside storage tank (developed technology)

Development of a moisture removal system by chemical treatment method (A Schematic Diagram)

04

Development of Combination Technology of Animal/Vegetable Oil- Animal and vegetable oils, which are generally used as raw materials for bioheavy oil, have different solvents and different thermal properties when de- examination and de-oxidation are performed according to their respective characteristics.

- Accordingly, the unique characteristics of each animal and vegetable oil are reviewed to select an efficient solvent, which in some cases results in improved de-examination efficiency and reduced time. (Advantages of mixed de-examination process)

- Depending on the type of vegetable oil and animal oil, there are some applicable mixing processes, and based on this, we would like to establish a database of mixing combinations.

- Efficiency can be expected to increase according to the multi-axis of production process time and the amount of mutual mixing.

- Development of deoxidation process